Steel manufacture is an essential process in different sectors, playing a critical duty in manufacturing elements and frameworks. This approach involves the production of steel parts through different procedures such as cutting, bending, welding, and setting up basic materials. Comprehending the subtleties of steel manufacture can give understandings into its extensive applications and the benefits it offers contemporary manufacturing.

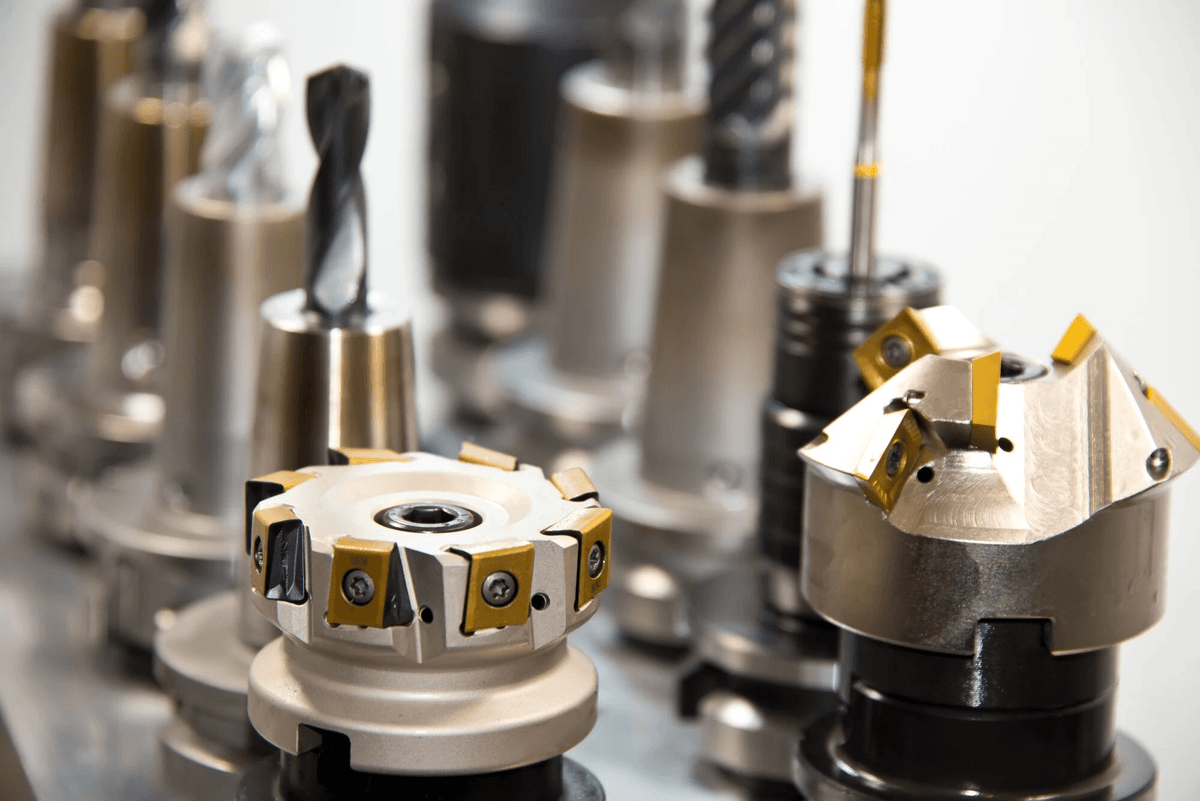

Among the primary techniques utilized in metal construction is reducing, which can be achieved making use of techniques such as laser cutting, plasma cutting, and shear cutting. Laser cutting is especially remarkable for its accuracy, permitting suppliers to produce intricate designs without the product's mechanical anxieties. Plasma cutting, on the other hand, is favored for its ability to reduce thick products swiftly, making it perfect for large tasks. Each reducing approach has its benefits, providing producers with adaptability in their operations.Get more info about metal fabrication article.

Bending is an additional key facet of metal construction, made use of to change the form of the metal while maintaining its stability. Techniques like press braking and roll forming are common, permitting intense angles and curves. Correct flexing methods are important to make sure that the finished item meets design requirements without jeopardizing the product's toughness. This action highlights the virtuosity associated with metal manufacture, as it requires a keen understanding of material buildings and layout concepts.

Welding is usually considered the backbone of metal construction, as it permits the signing up with of steel parts securely. Various welding approaches are used, including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and stick welding. Each strategy offers different benefits, depending upon the kind of metal and the preferred toughness of the end product. Experienced welders can generate joints that are stronger than the base materials, showcasing the importance of this process in construction and manufacturing.

The application of steel manufacture spans throughout numerous sectors, consisting of automotive, aerospace, building and construction, and also art. From the framework of buildings to the parts of detailed equipment, made metal parts are essential to the performance and resilience of numerous items we utilize daily. Moreover, as sectors continue to innovate and advance, the demand for innovative metal fabrication techniques is only expected to climb, leading the way for improvements in performance and sustainability.

Finally, metal construction is an essential process that encompasses a variety of strategies and applications. Understanding the details of reducing, bending, and welding offers a deeper admiration for this vital production self-control. As modern technology developments and markets expand, the value of steel fabrication will certainly remain to grow, making sure that it remains a keystone of modern-day commercial methods.Here is an alternative post that provides more information related to this topic: https://en.wikipedia.org/wiki/Metal_fabrication.